Carbon Headliner With Media Player

With little to no room left on the dash to land any kind of a simple head unit to use with the stereo, I decided to look to the last open real estate left in the cab: the headliner. The plan was always to remake the headliner in carbon to replace the flimsy drop cloth used from the factory. It was an added bonus to use some of that open area for some actual utility in the cab. The ergonomics were spot on from some physical measurements as to where to land the head unit, just out of sight enough to not be distracting but easy enough to see and adjust when needed. The marine based Fusion head unit also had the bonus of having no real internal amplifier, making it incredibly small and light with no real heat generation which was perfect for stashing it in the thin carbon headliner above.

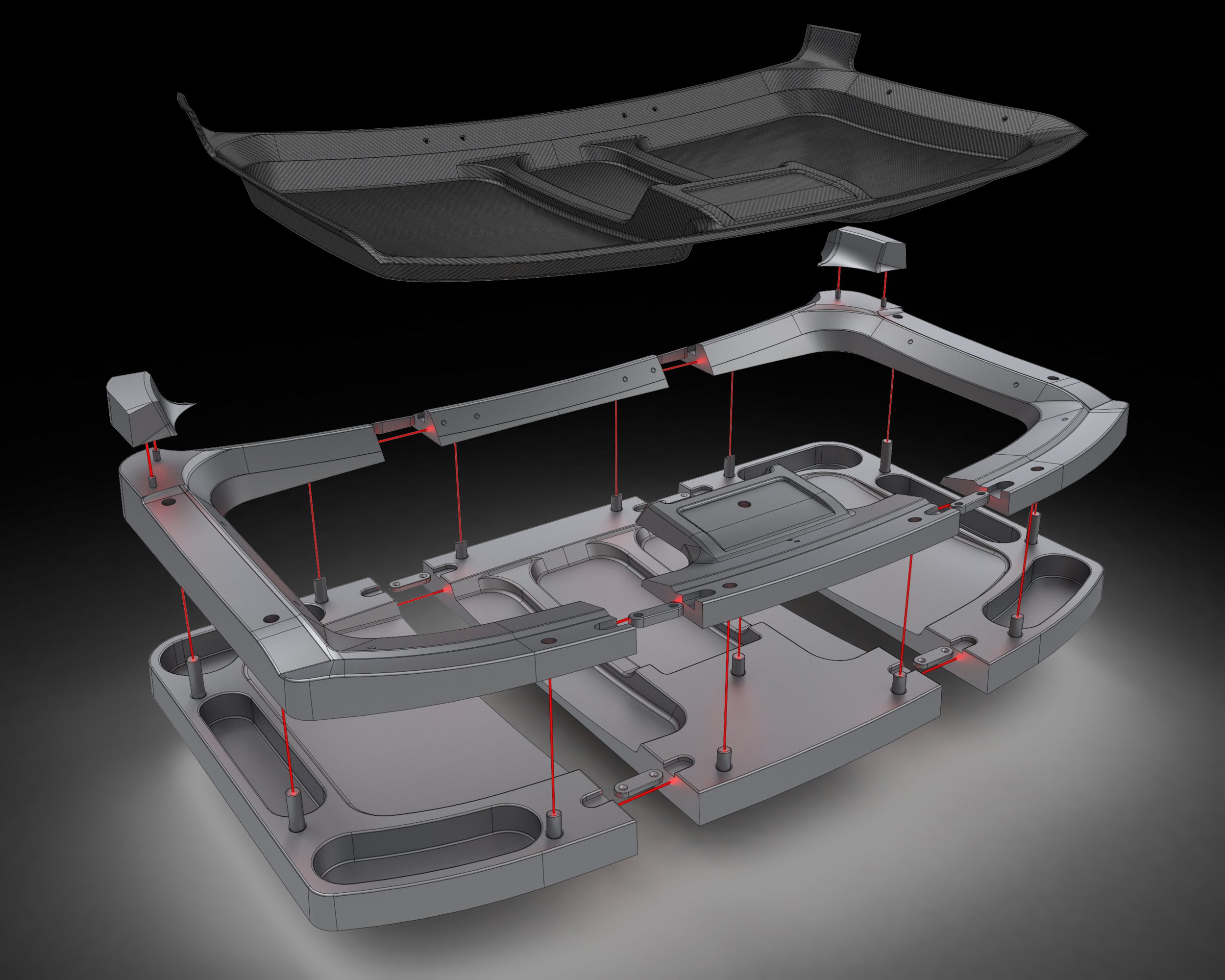

The male plug was a bear and one of the largest I had designed to date. It needed to be broken into 7 separate pieces to make it manageable to machine on my home CNC 3-axis router, which only has a realistic cut volume of 33”x 33”x 5” inches high. The mold sections were all strategically designed to interlock into each other, distributing the seam lines across the widths of other sections and using dovetail blocks to reinforce all the joints. Dowel locator holes were also milled into all the sections to assure alignment as each piece was glued into the next.

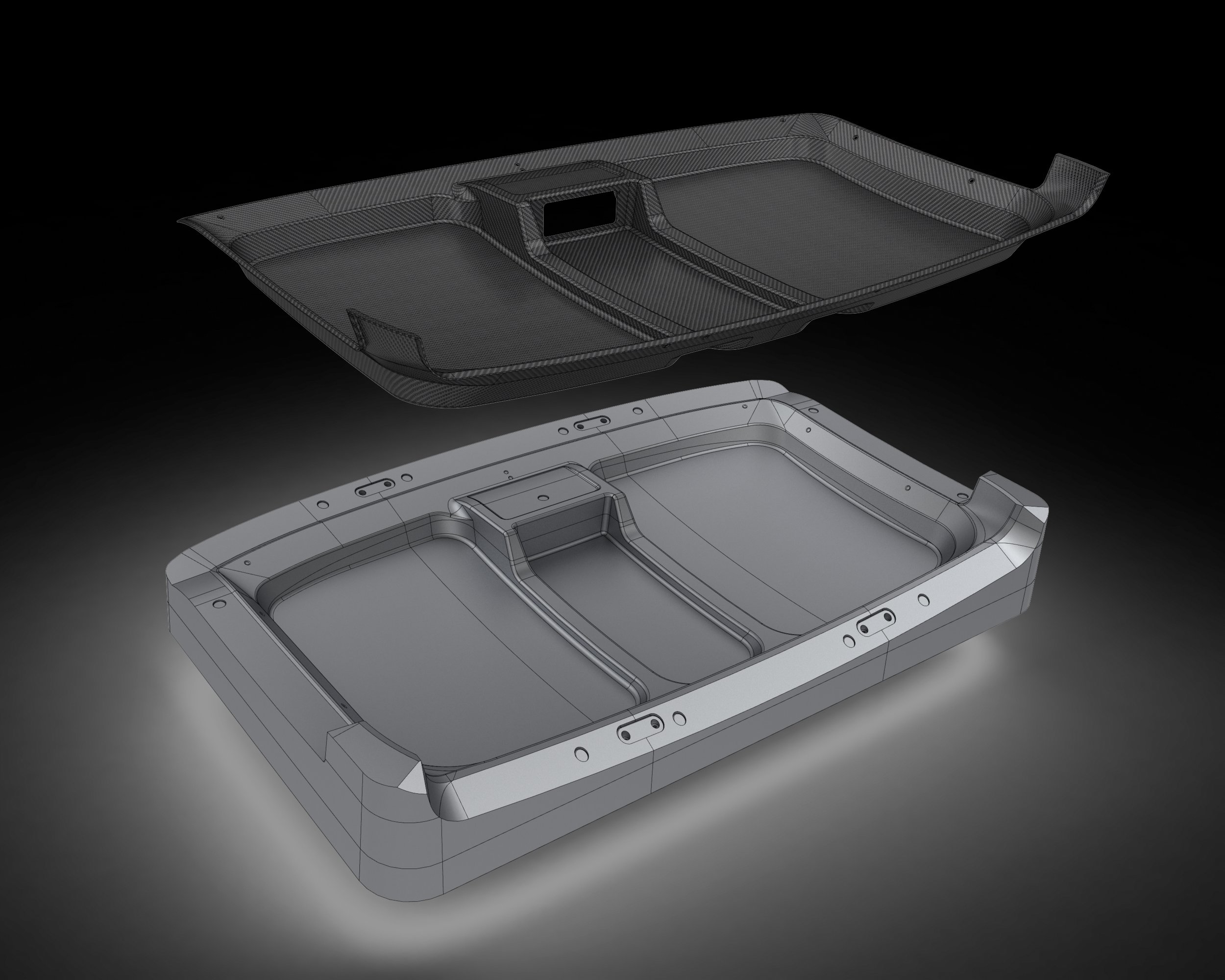

Once the male plug was entirely assembled, there was a considerable amount of time in body working the large and complex structure to a smooth high gloss shine. The traditional process of release agent, gel coat and hand lamination of fiberglass was used to generate the female mold from the male plug.

The female mold was treated chemically for release and the part was very tediously laid up with carbon cloth. The detailed peaks and valleys in the mold required very precise 1:1 templates to be made from the CAD model to trace over and cut out the carbon cloth, to ensure the layup hid as many of the seams as possible. After being resin infused with epoxy, the part was pulled from the mold and looked amazing.

The part was trimmed, hole drilled to accept the head unit, and fit into the truck’s cab with little effort needed. The headliner was the perfect piece to really clean up an otherwise boring area of the cab, and squeeze out a few proper amenities for the driver and passenger while doing so.