Carbon SHOCK SCOOPS

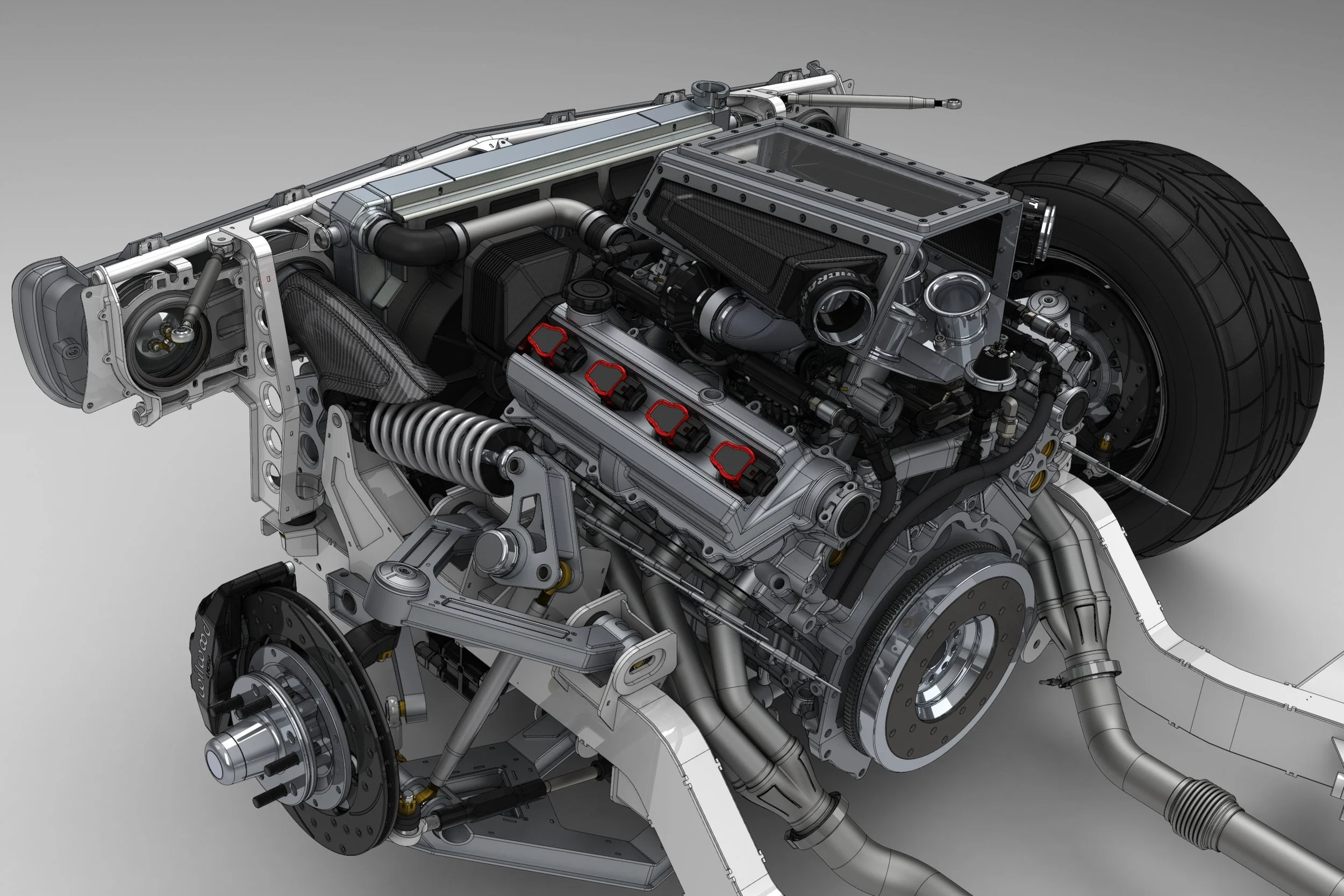

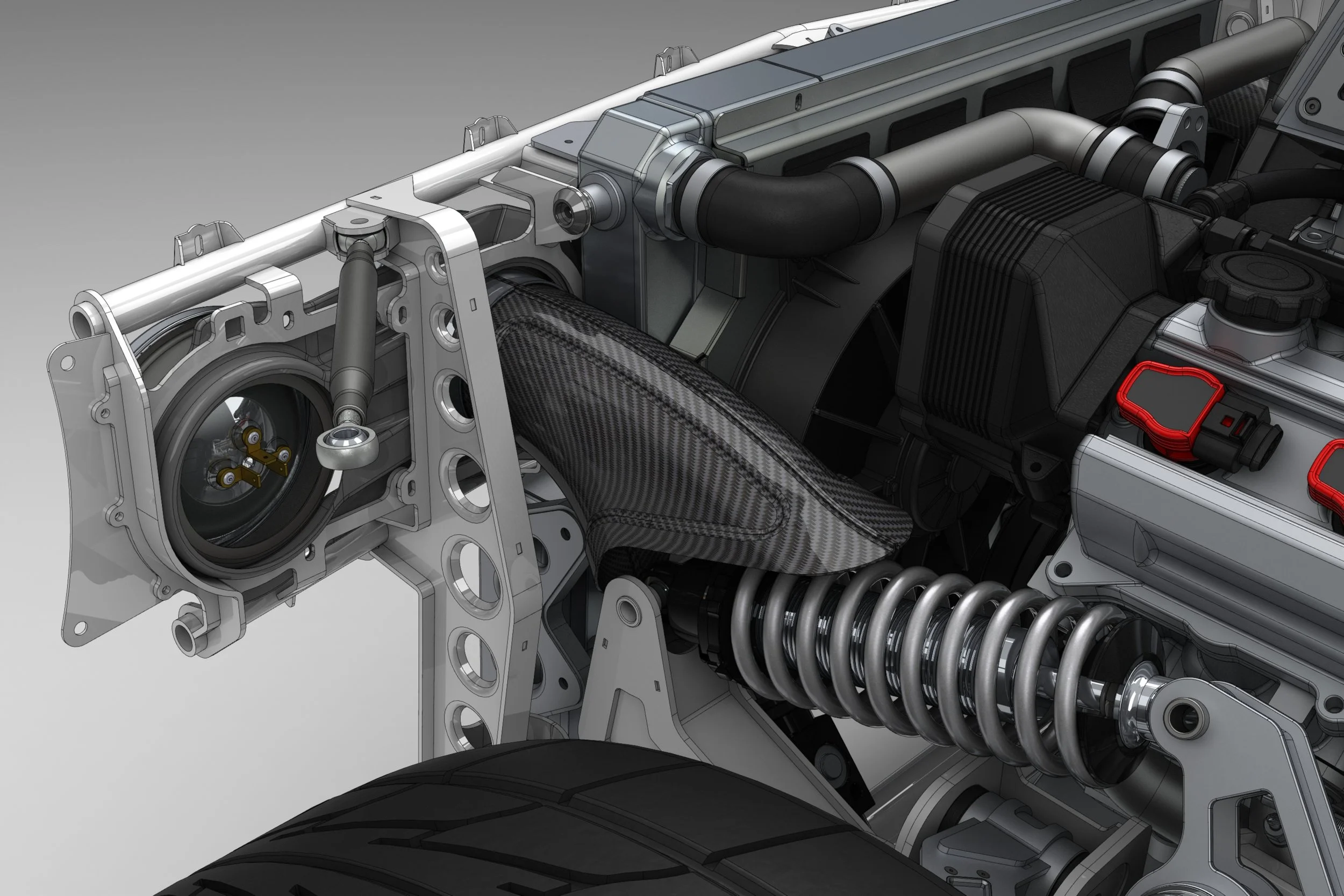

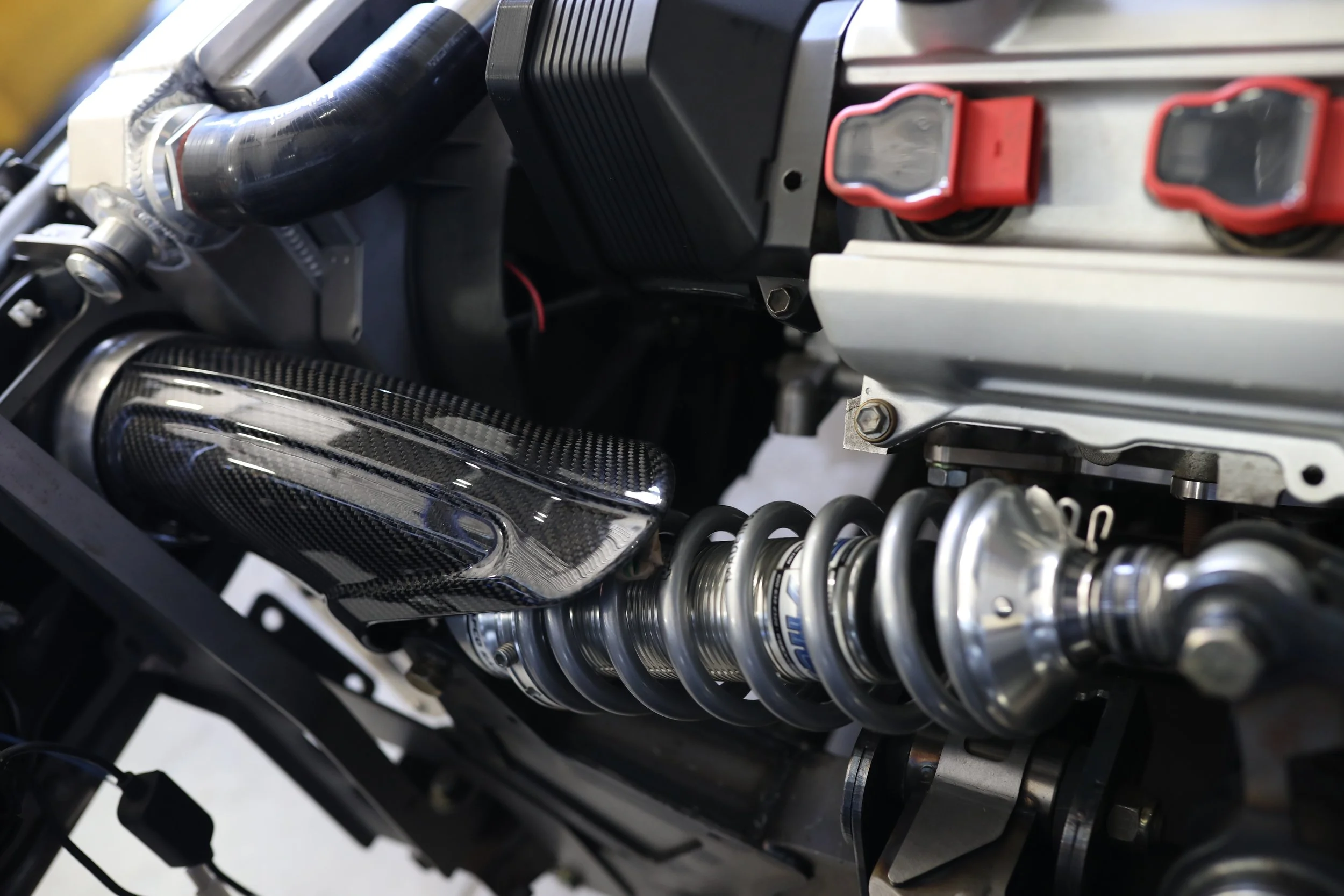

The cantilever front suspension places the coilovers out and forward in the engine bay of the Datsun 620 build, tying the coilovers back into the front structure of the chassis. While the coilovers have been placed as far from the engine as feasible, the shock bodies still lay very close to the first two primaries on the exhaust manifolds. Managing the heat soaked into the coilovers at this point has always been a concern, but the no longer utilized ram air scoops of the inboard headlights have been sitting since switching from N/A to twin turbo. Tying back into these unused design features, I designed some simple lofted air scoops to terminate the forced air over top of the coilover bodies for additional cooling. This also went a long way to balancing out the visual of the front engine bay, where the empty ram air provisions seemed very out of place.

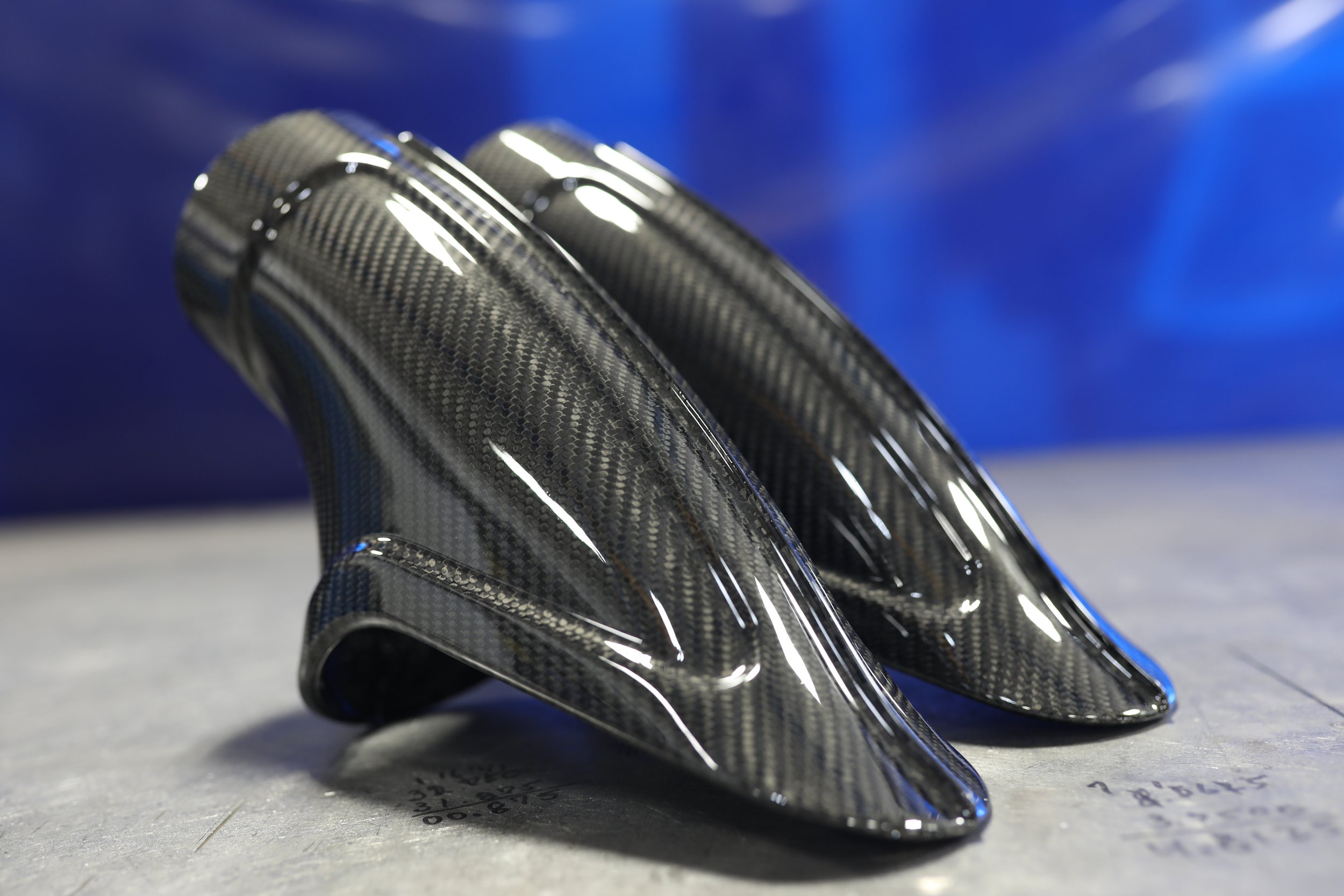

Once the designs were finished, I 3D printed each half profile of the scoop to be body worked and polished to a high gloss. These bucks were then glued to melamine board with filleting wax around their profile, to provide the entire plug profile for the female molds. Traditional mold making was employed to hand laminate the female mold over top of the plugs, and provided clean half section molds to infuse the carbon intakes.

The scoops were resin infused with carbon reinforcement using epoxy resin, then trimmed for the two half sections to be bonded together to create one mirrored profile. After final clear coat, the scoops were mounted inside the engine bay around the ram air headlight buckets for a fantastic fit and visual.