fabricated control arms

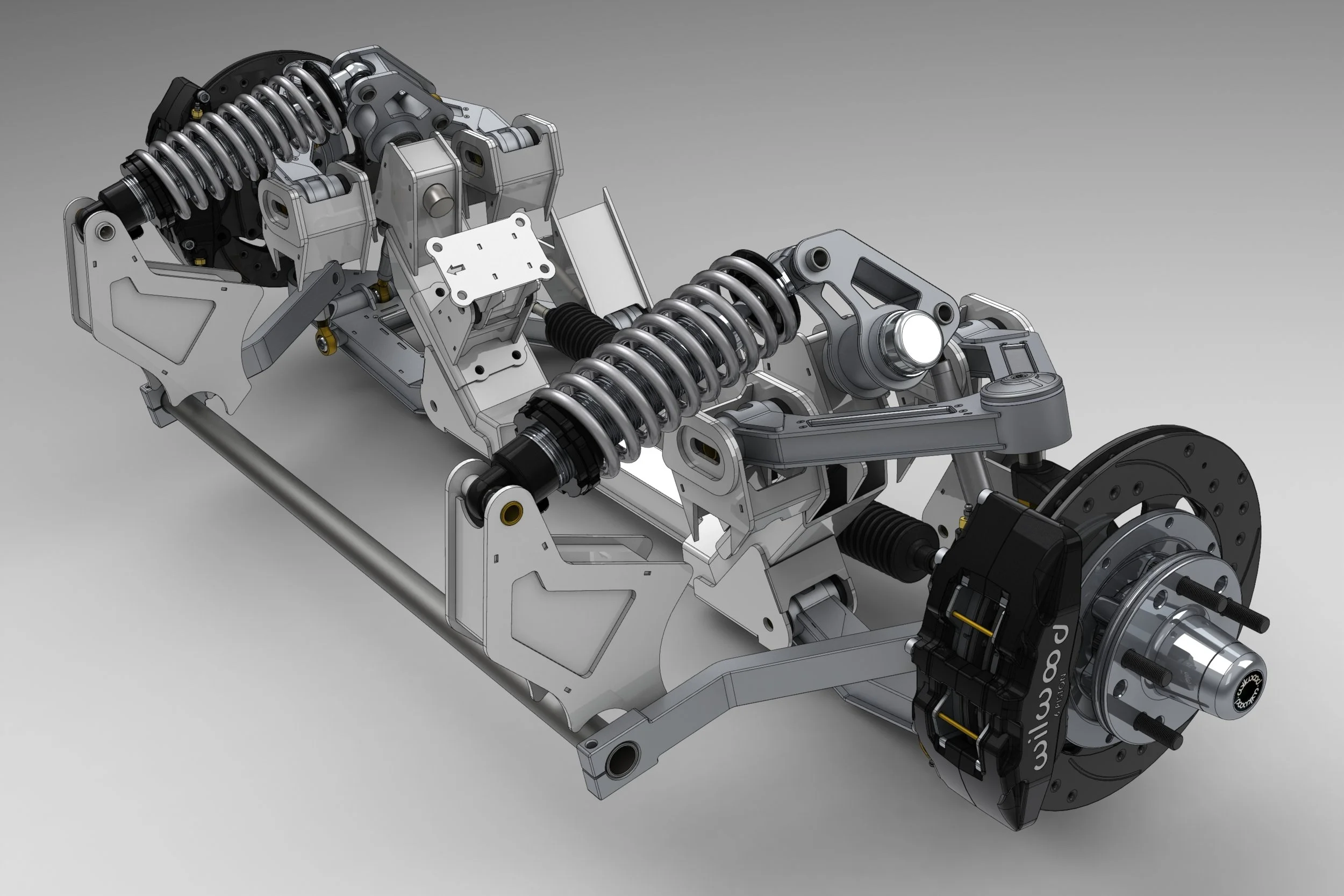

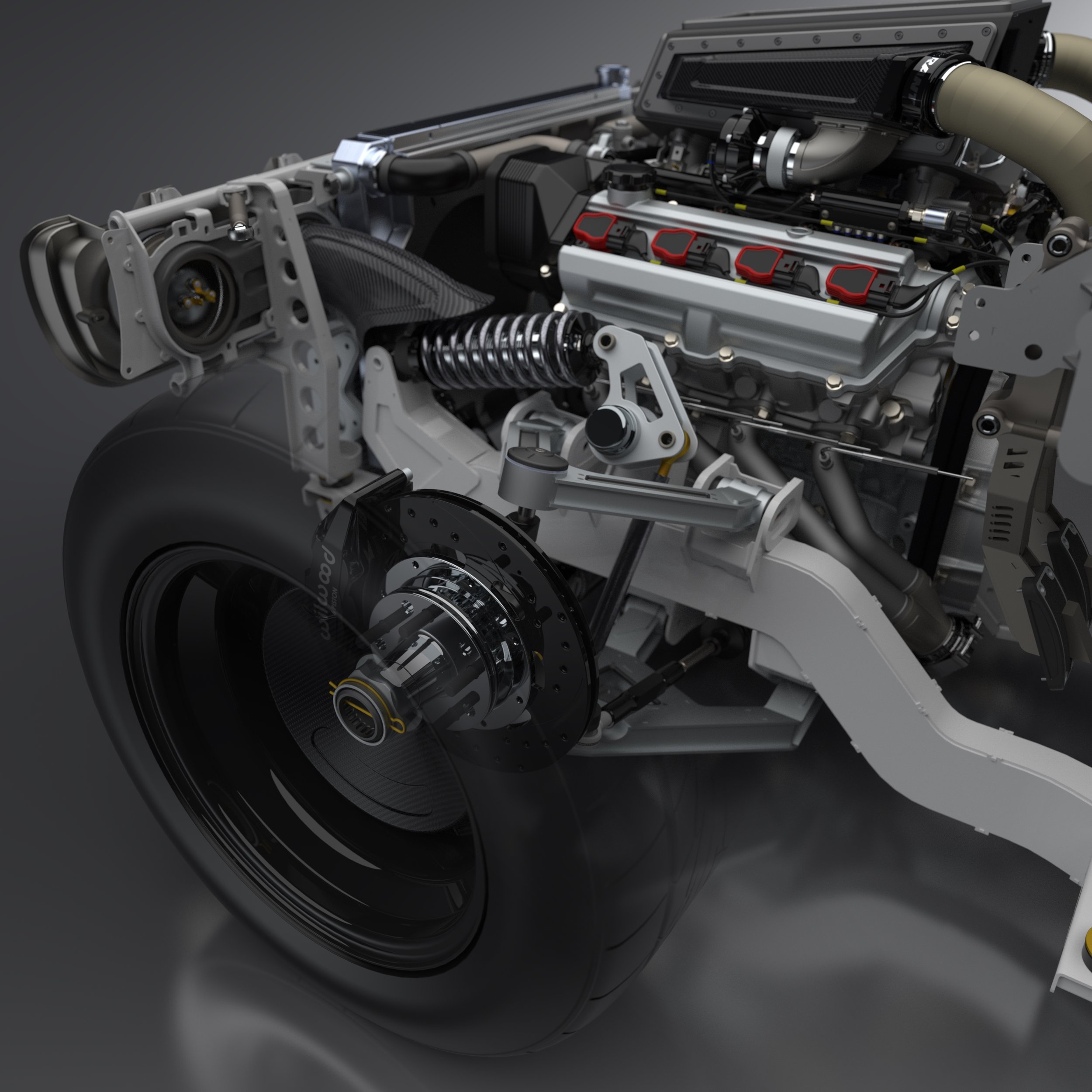

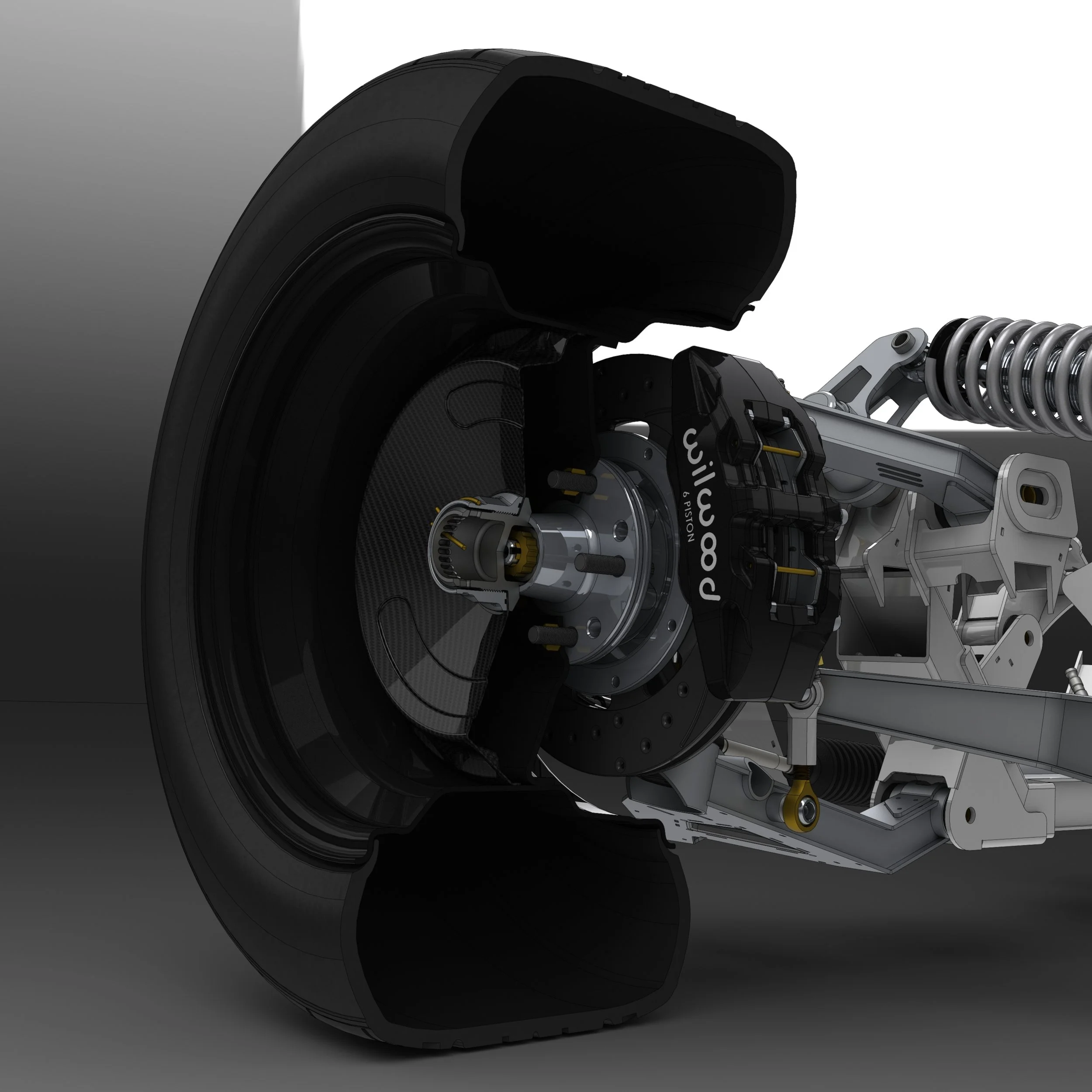

As an additional part set of the Datsun 620’s custom chassis, a full set of fabricated control arms were designed and built for the one-off independent front suspension. As a design exercise to create a set of unique and properly functioning arms on this project, it was also an opportunity for more hands on experience with welding and fabrication using a design of my own.

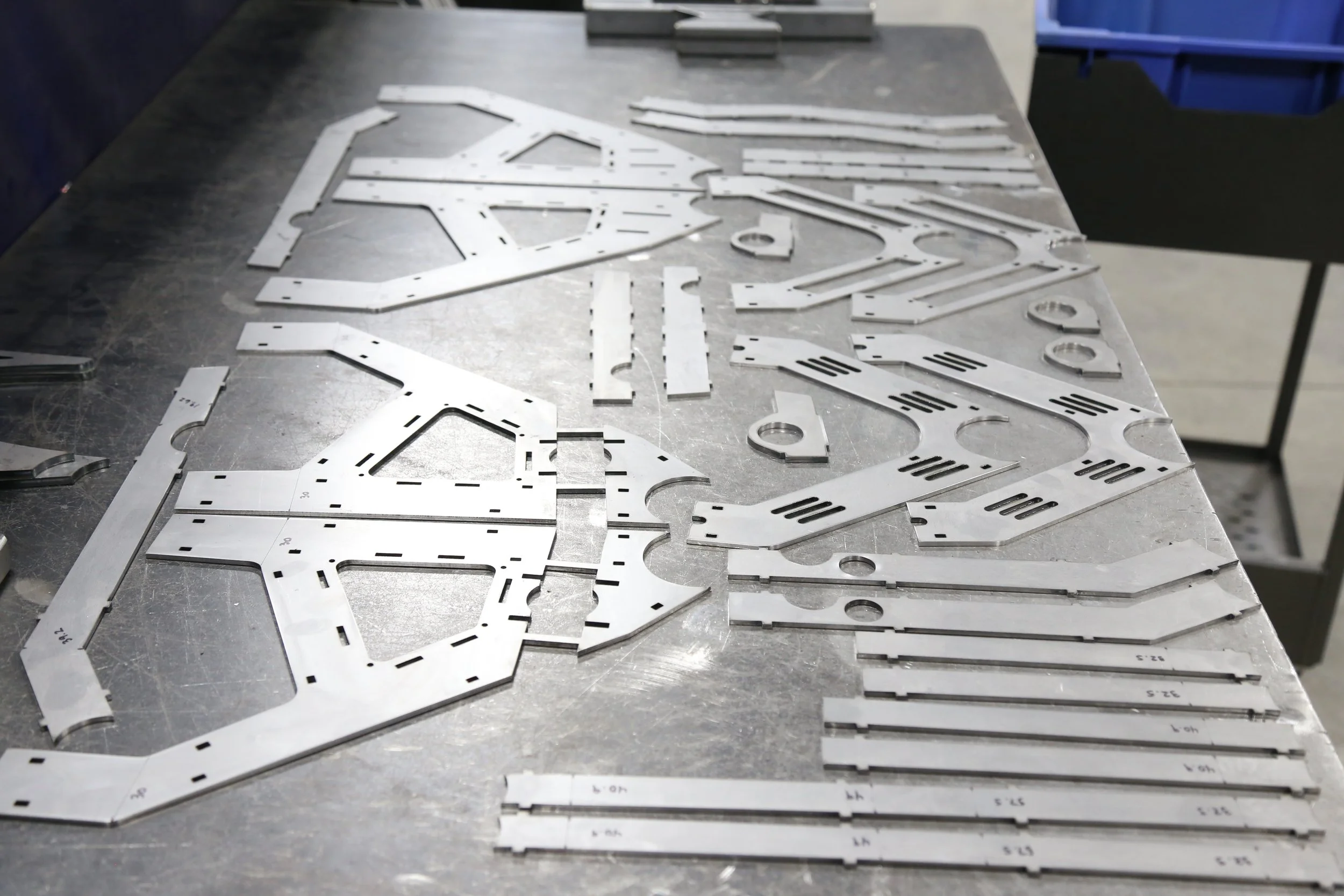

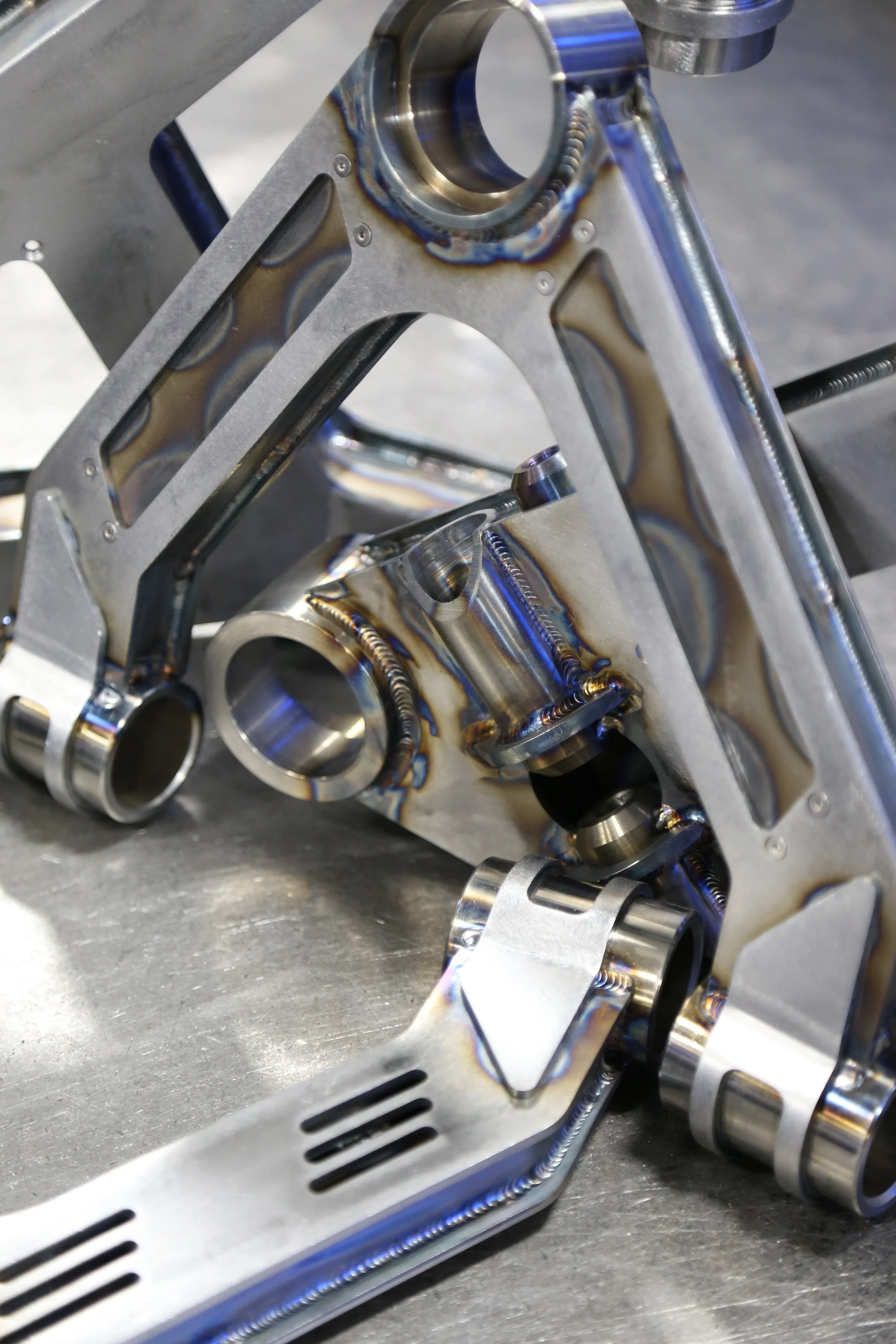

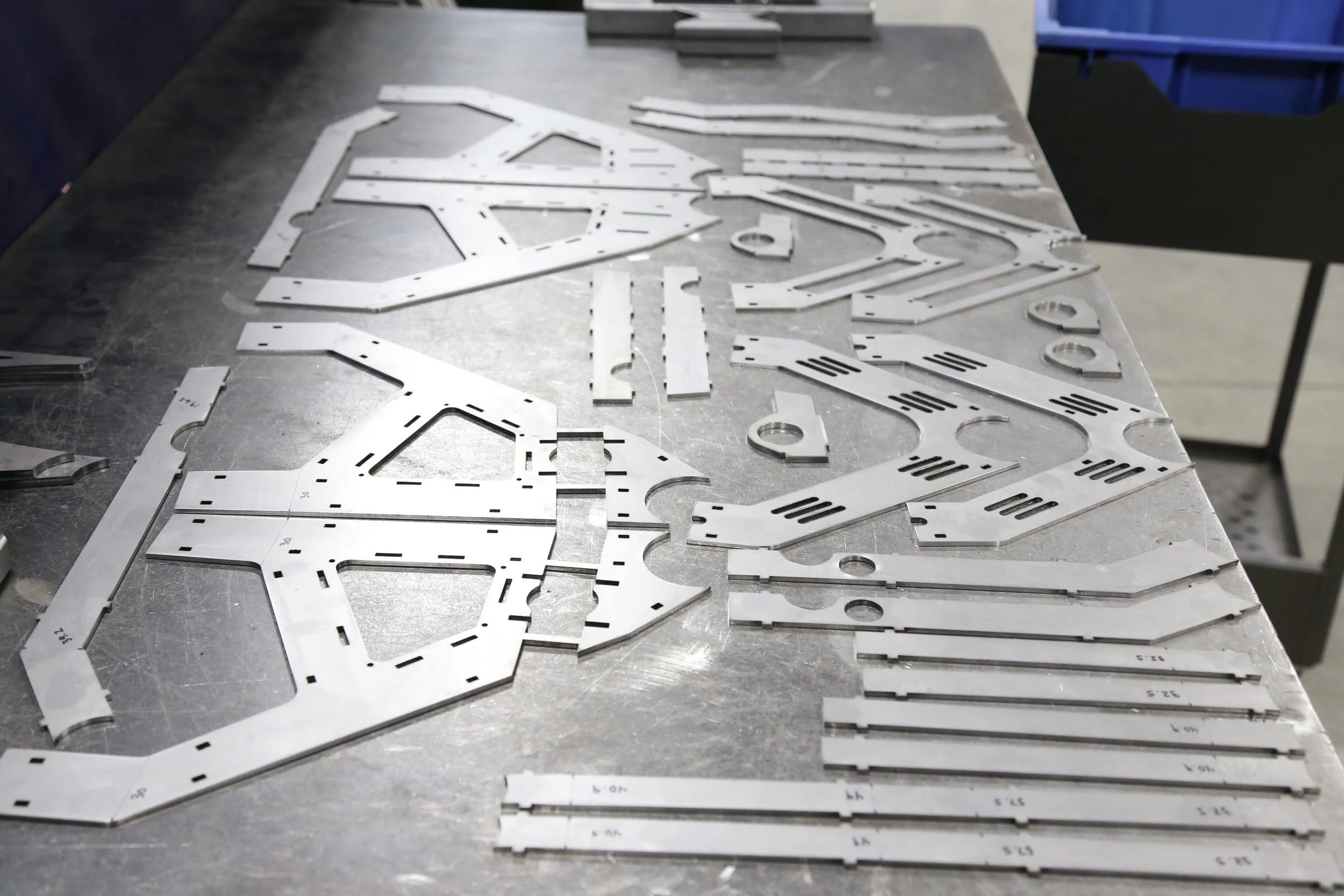

The control arms were mainly inspired by the off-road community, having a very fabricated and trophy-truck design flow. The arms used an I-beam structure with interlocking tabs on all interface components, allowing them to lock together after bending and forming their individual part shapes. Once all the parts were laser cut, cleaned and press broke to spec, they were assembled together while clamping the interlocking tabs into place. The arms were then tack welded together, and fully welded out on the bench. Pivot end and balljoint weld cups were added last and jigged into place after the main arm was allowed to be welded and move/shrink. This gives the arms the ability to slightly distort but not affect the overall geometry defined by the pickup points at all 3 corners of each arm.

The arms also received counterbored mounts for the bellcrank push rods, which were hand lathe turned from mild steel. Lapping plates were added around all the pivot cups at the inboard ends of the arms, ensuring a generous amount of surface area weld. While my TIG welding certainly isn’t perfect, I am constantly trying to improve my skill sets and learn along the way.