Carbon fiber intake filter boxes

The rear mounted twin turbo system on the Datsun 620 build left some challenges on where to place the air filters and how they are fed clean, flowing air. Not wanting the filters to just sit in pressure bubbles either in the top of the bed or underneath, the best approach was to design filter boxes around the air elements that could be force fed clean air from the outside of the truck. Boxes were designed to mount underneath the bed of the truck, with inlets designed to directly feed them air off the rear over fenders’ front faces.

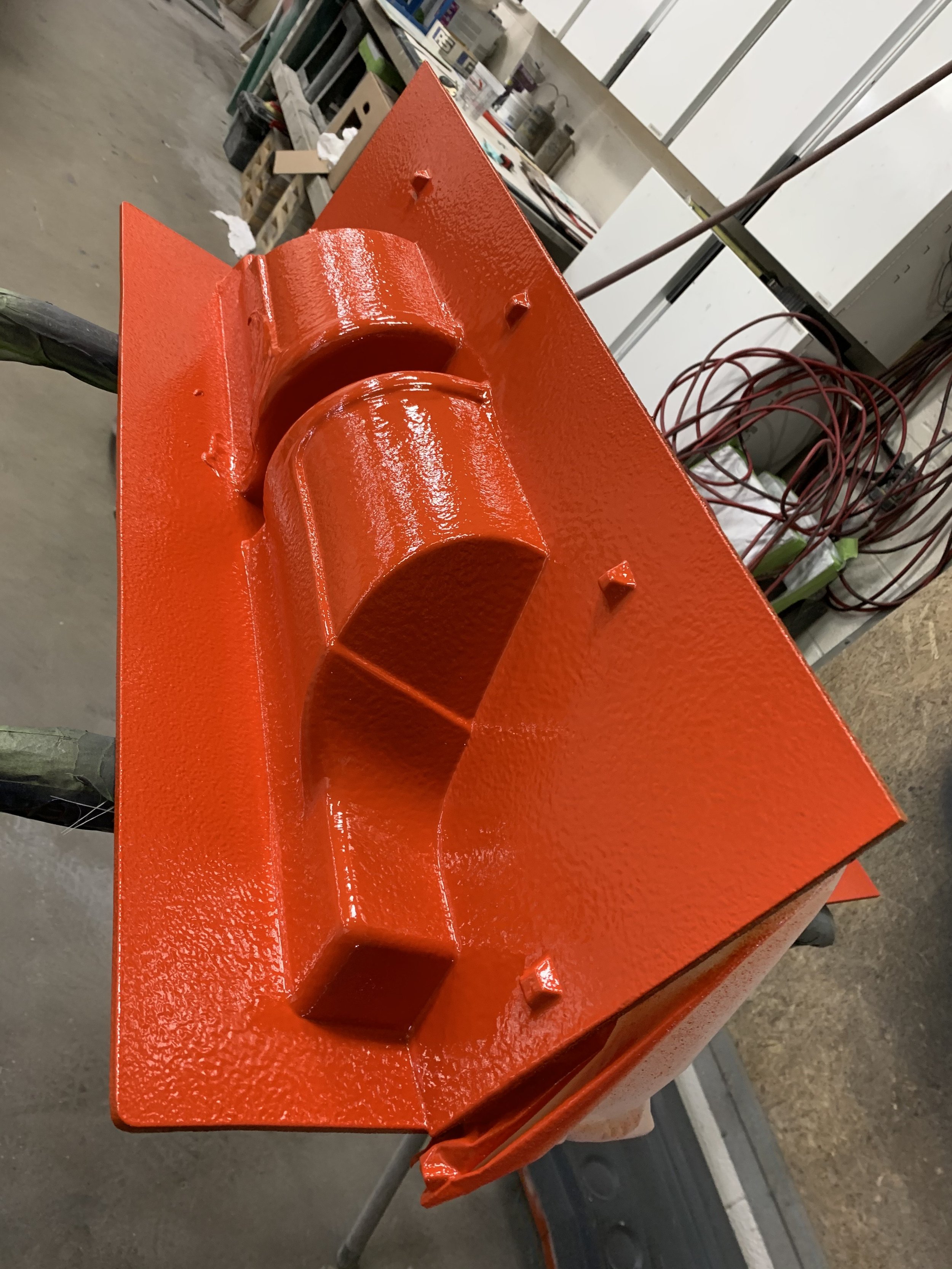

Planning for the boxes to be made from carbon, 3D printed male plugs for the mirror imaged filter boxes and lids were made and body worked to a high gloss. The boxes had their molds built as two piece slit sections to draft their geometry, while the lids only needed a single draft mold. Once molds were created, all parts were resin infused using carbon reinforcement and epoxy resin.

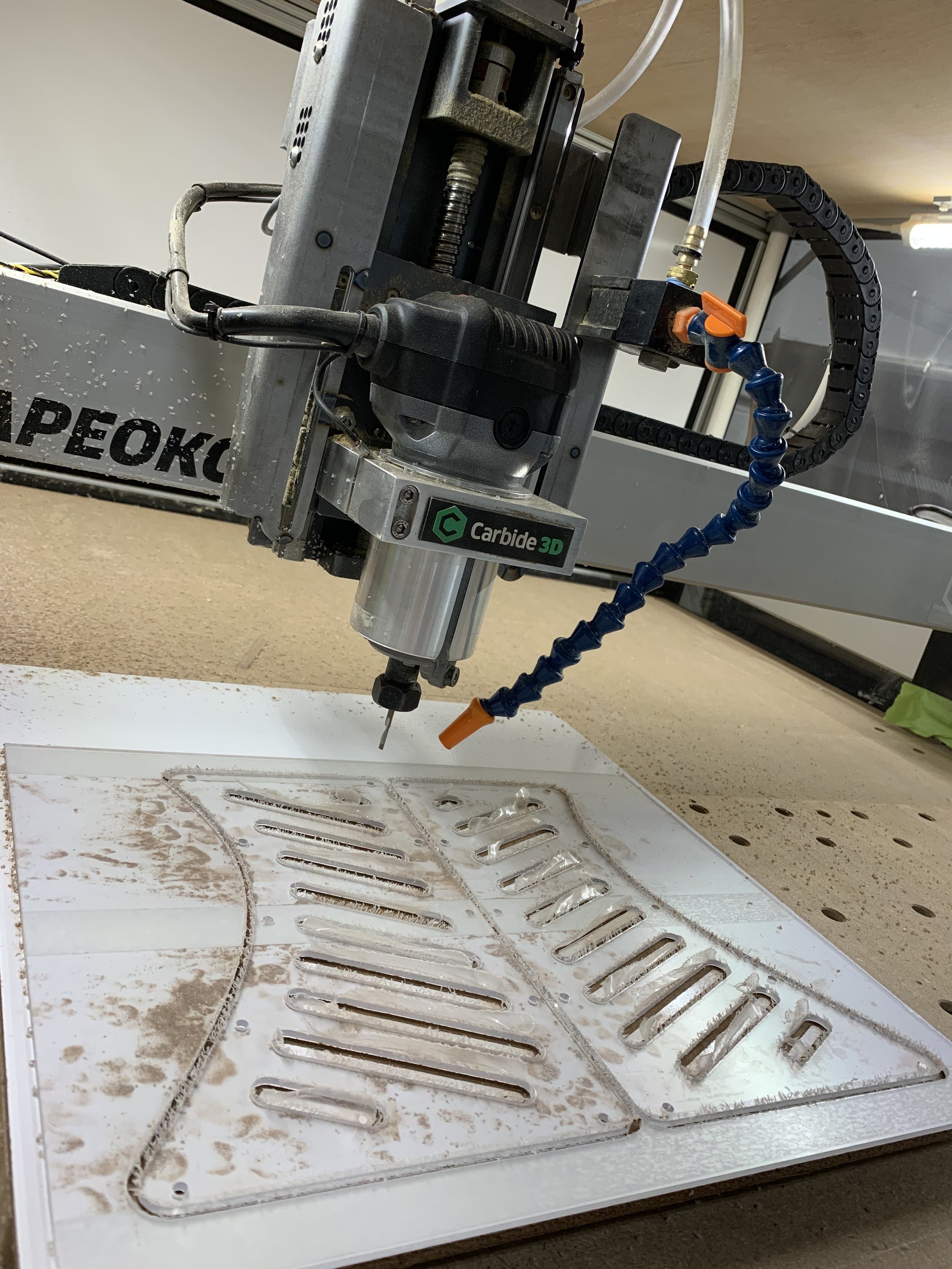

The box’s lids were designed to receive a plexiglass window in a recessed window frame on the carbon parts, with that lid having pass through slots for air if the filters are not consuming all the air being forced into the box volume. These parts were programmed and machined on my home 3-axis mill, then heat formed over a buck profile to create the needed curve to fit the lid profile.

After final fitting, drilling, and clear coating the assemblies came together beautifully and were ready for service on the truck.