Carbon FOOTWELLS

With virtually all corners of the Datsun 620’s interior draped in carbon, it felt off to leave the footwell areas for standard carpet. I designed and provisioned for the driver and passenger footwells to receive full carbon surrounds, including dimple die’d aluminum inserts at the contact points for the driver and passenger’s feet. This did a great job of visually balancing out an otherwise boring area, and really tie it in with the rest of the interior.

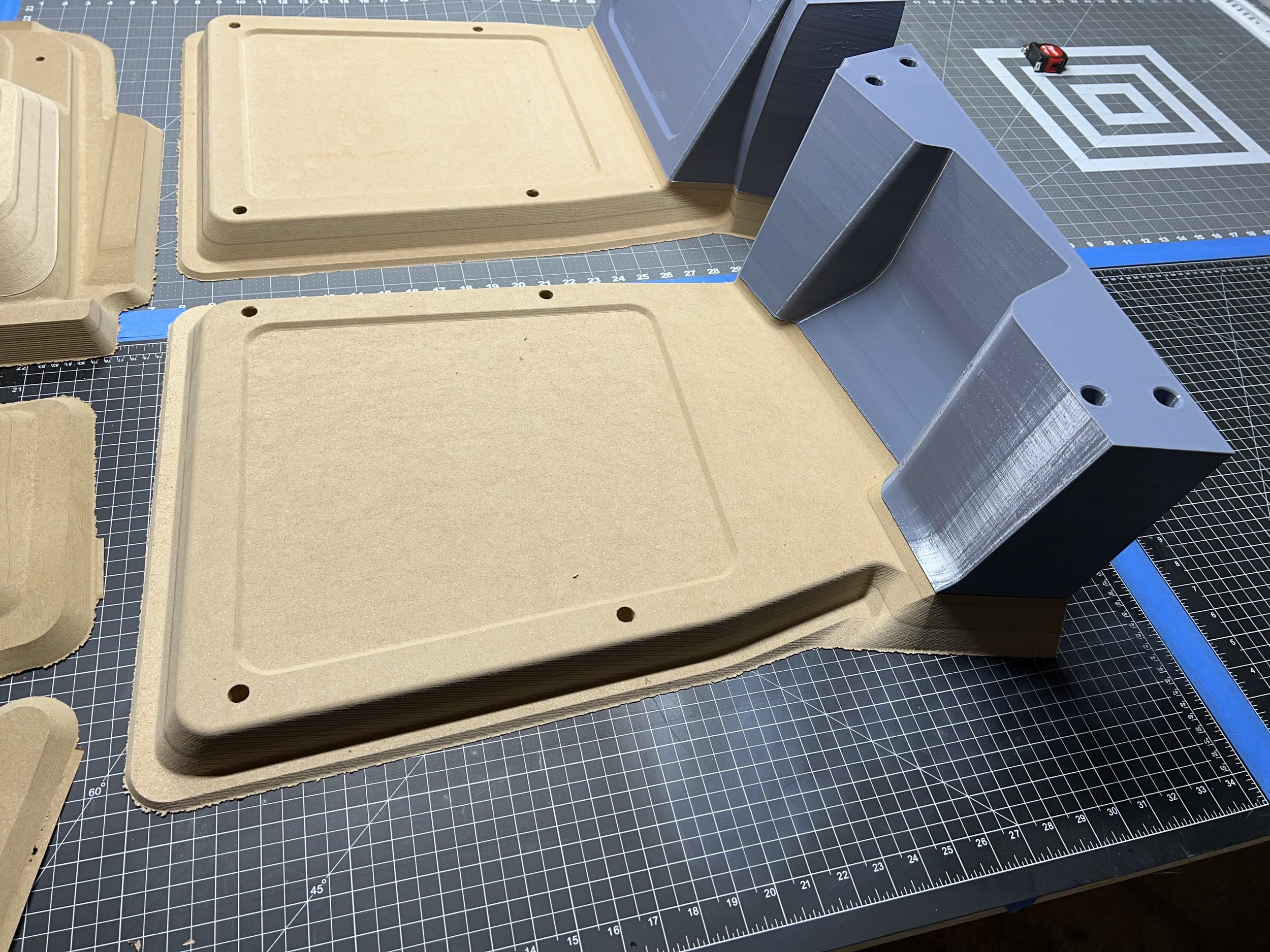

The large and complicated patterns were best served by making them from two different process: 3D printing and 3-axis machined MDF. the large flat basses were easily machined from stacked MDF, and the upper sections were 3d printed due to their tall and complex shapes. I was a bit worried about bonding the differing materials and how the seam lines would transfer through with the exotherm of the mold, but these two materials paired together really well. The plugs were body worked to a high gloss and female fiberglass molds produced over them.

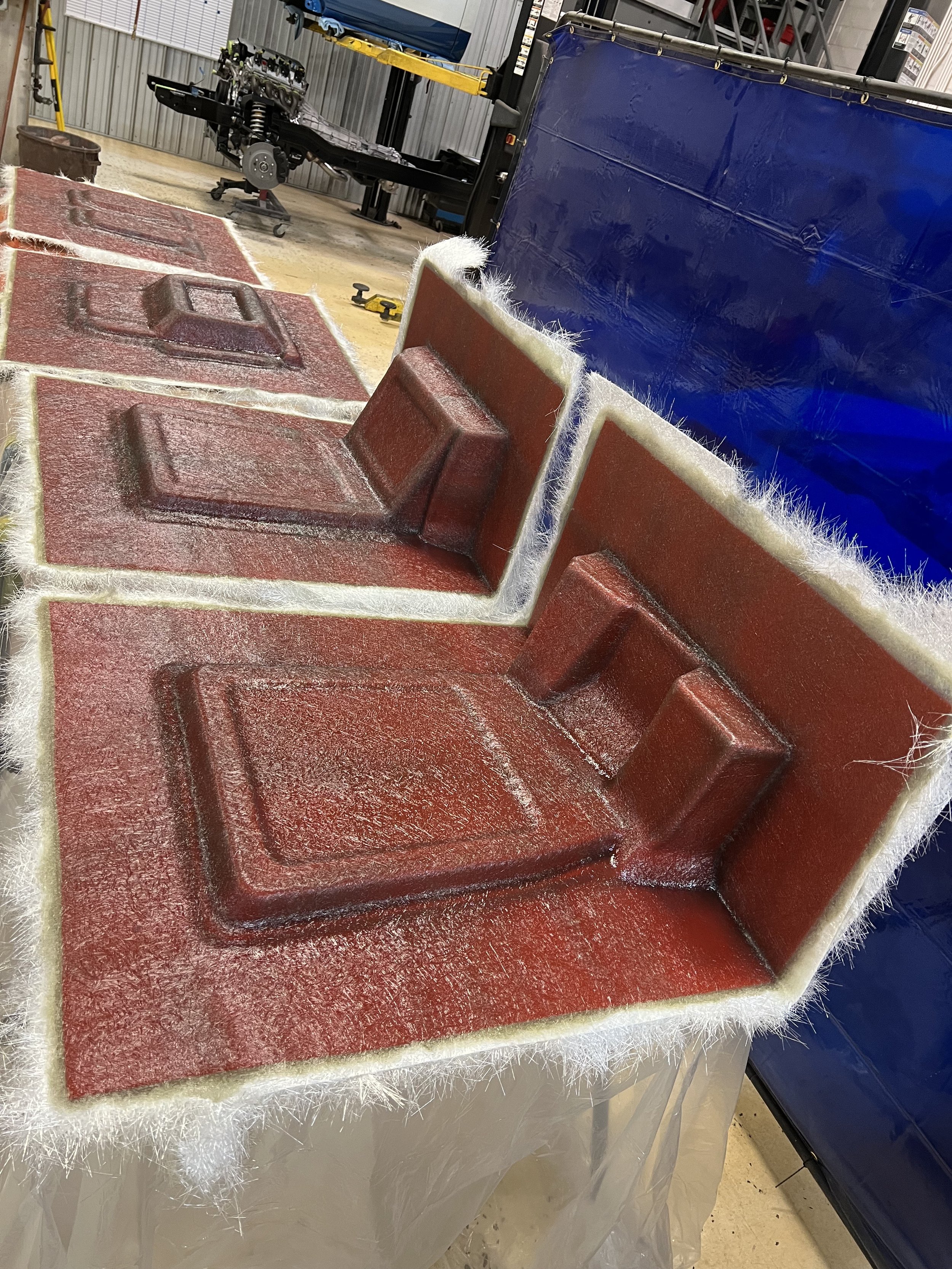

From the fiberglass molds, full carbon parts were resin infused using epoxy and left to cure for 24 hours. After demolding and trimming the parts, the aluminum dimple die pieces were milled to shape on my 3-axis CNC router and pressed to shape using bell form dimple dies. Once together, they were installed into the cab for a glove like fit around all the body lines of the interior.