Bellcrank remote brake and clutch system

Knowing that I didn’t have very accessible room in the engine bay for all the brake and clutch system hydraulics, I had to think a bit outside the box on how to handle these systems. The wide 1UZFE V8 engine made packaging difficult, and the look of a clean and symmetric firewall was an aesthetic I really wanted on the build. The cab of the truck was receiving a new dash bar system on removable mounts, and after some careful planning it looked as though mounting all the system hydraulics in the cab of the truck was going to be a great solution.

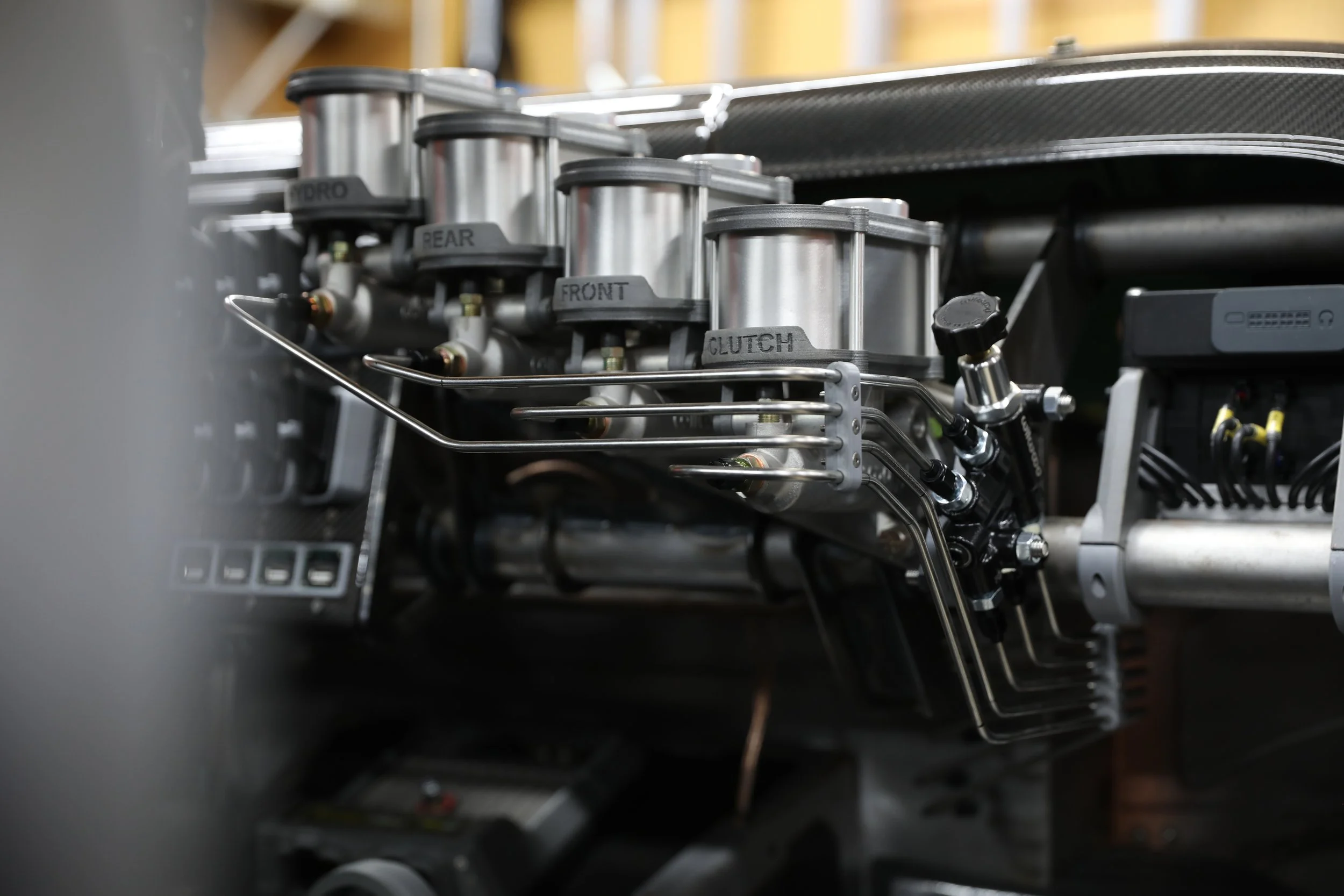

No stranger to these types of remote actuated designs, I started plotting out the locations and provisions needed for all 4 system master cylinders in the maser CAD assembly. Front brakes, rear brakes, clutch and hydraulic e-brake all had individual master cylinders that needed to be mounted and actuated with the correct ratios and resolved forces through full motion. Bellcrank arms with heim ended push rods translated the motion from each pedal/handle across the dash and actuated each respective master cylinder. The mounting structure was kept as simple and light as feasible, while still leave a large margin of safety in the design.

The master cylinders looked very plain with the cheap standard plastic reservoirs on top, so the reservoirs were redesigned from the ground up to be fabricated aluminum units dressed with 3D printed glass nylon trim. The 3D printed pieces would also have labels on each reservoir to show the function of each system for more clarity (and avoid everyone asking what they are all for).

Lastly, since the hydraulic system was now a showcase item inside the cab, I knew I wanted all the hydraulic lines to be routed in a very aesthetic and flowing manner on their way to a bulkhead point on the firewall. The brake lines make their way to a proportioning valve before being divided between both fronts and a biased rear, and the clutch and e-brake lines follow underneath. They all terminate on a custom machined billet bulkhead system made on my home 3-axis CNC router.